On Saturday 14th June we turned over our new-build tender chassis to get it the right way up so we can finish off the last remaining pieces of work before re-wheeling.

At this point, the chassis weighs approximately 5 tons, so obviously turning it over with our 2 ton gantry crane in the workshop is a non-starter – even if there was room to do so. This meant that the chassis needed to be moved outside. The easiest way of doing this would be to roll it out via the AVR goods shed, and transport it by rail into the yard. However, because of other priorities, the AVR wasn’t able to support this move, so we had to go out the other way, via our roller door. Unfortunately, this meant moving our largest machine tool – a DeVlieg Jigmill out of the way a little – an operation which required jacking it up and moving it backward by about 10 inches so that the chassis would be able to squeeze by.

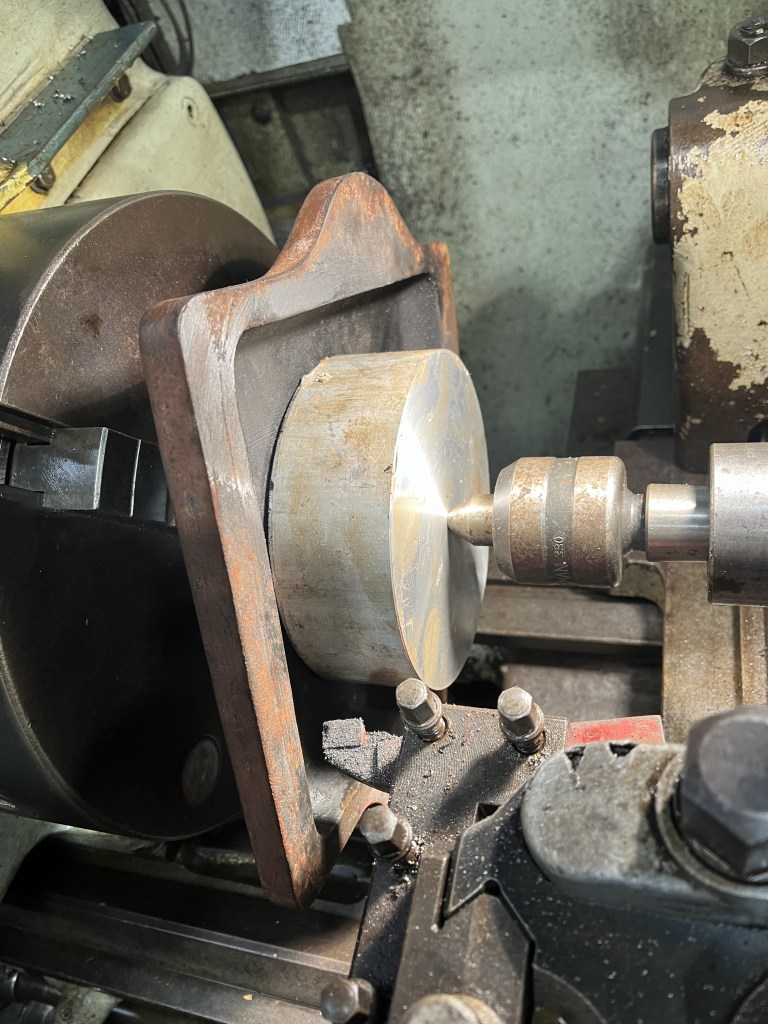

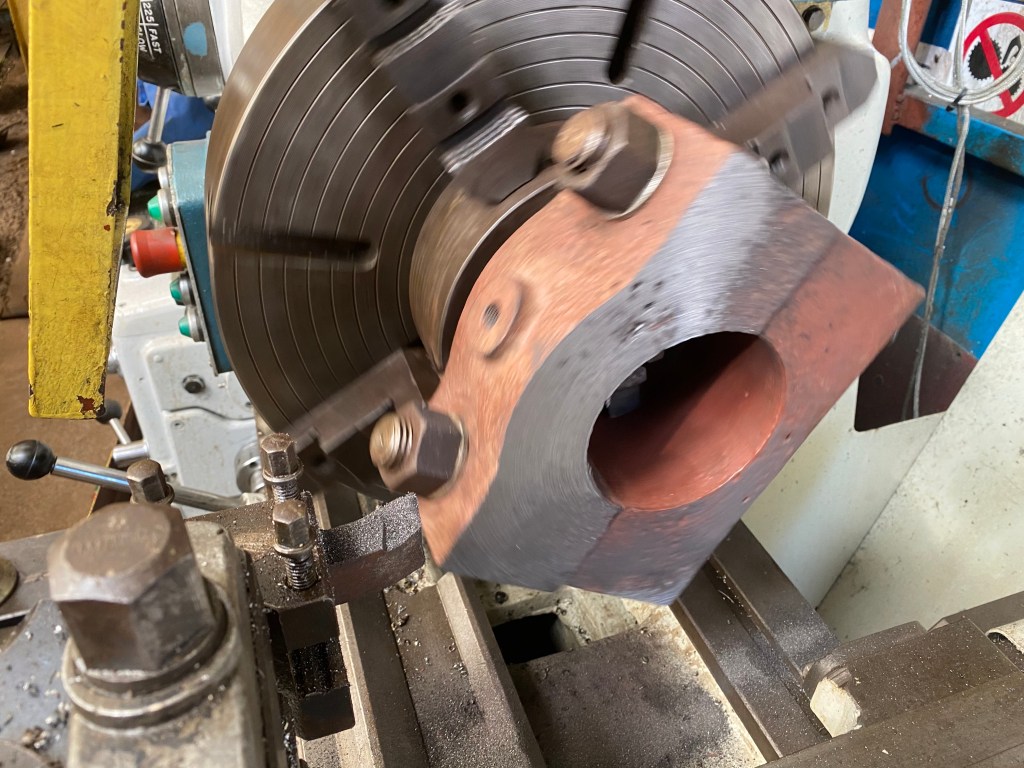

The following series of pictures show how we got the chassis out of the workshop and turned it over.

Once the chassis was outside, the opportunity was taken to complete some more of the painting on areas which would be inaccessible or harder to paint when it was the right way up.

The day of the lift saw us hiring in a very large truck-mounted crane (or Hiab) to lift the chassis into the AVR yard which is nice a flat and has plenty of space for such an operation. To ensure a safe operation, we carried out a full risk assessment and method statement – writing it all down enabled a few things to be thought through and adjusted prior to commencing work.

Up she goes – the chassis being lifted on one side to commence turning it over.

Landed safely, and ready to be dragged back inside.

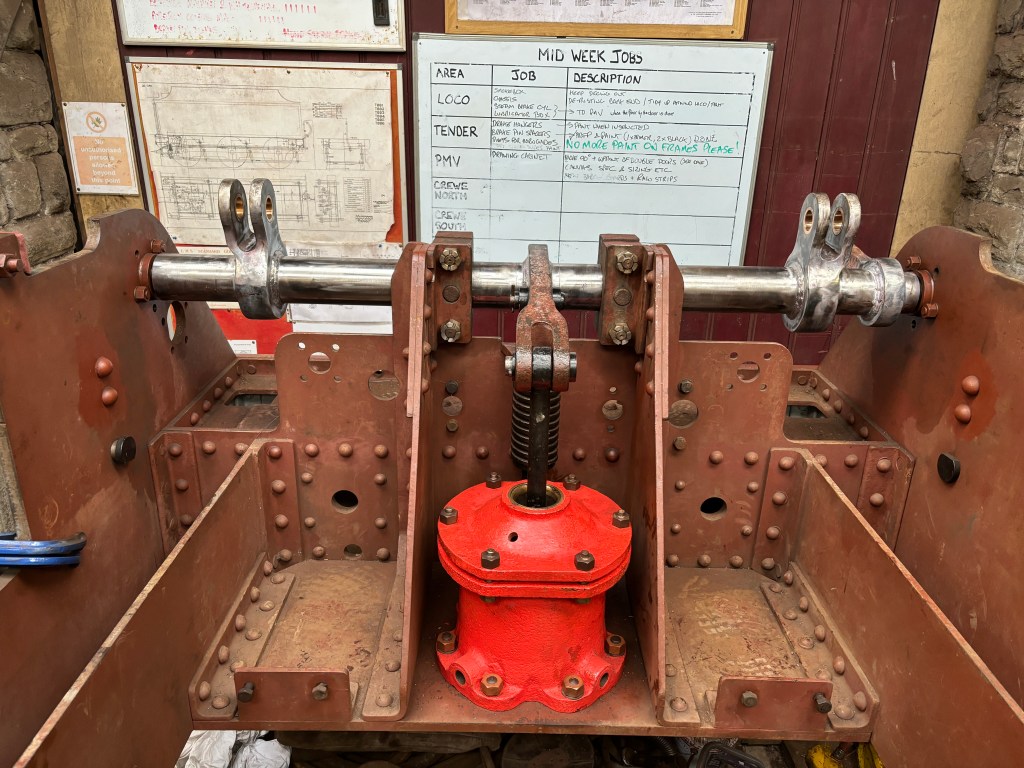

Going back a month or two before the move outside, and will all the brake hangars and linkages refurbished, we took the opportunity to do a trial fit of the tender brake gear. It all fitted nicely and even operated perfect on air (instead of steam). Although it would have been nice to leave it in place, it had to be removed for the turn over operation – and will also need to be absent when the tender is re-wheeled. Only then can we install it for the final time.

A view looking towards the rear of the tender showing the brake gear in the process of being fitted up.

Reminder that there are lots more pictures from the construction of our new tender chassis on our Flickr page. https://www.flickr.com/photos/4123lms/